The wider your margins between product costs and the cost of goods sold (COGS), the higher your profitability. One of the best ways to improve your profit margins is to focus on the cost per unit of your SKUs. By bringing down these costs, you can improve your ecommerce business’s bottom line with every item you sell.

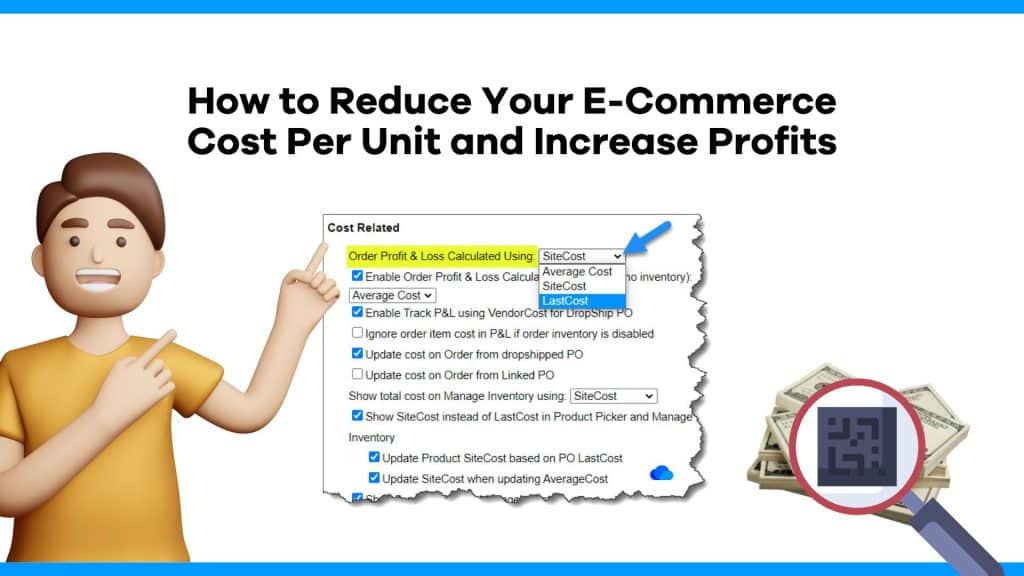

Cost per unit is calculated by combining all expenses associated with producing, acquiring, storing, listing, selling, packing, and shipping an item. If inefficiencies arise across one or more of these stages, you will not maximize your profit potential. Descartes Sellercloud makes calculating item costs simple.

What’s more, by tracking item costs over time, you can identify areas of your supply chain and fulfillment workflows ripe for optimizations—improvements that can potentially boost your profitability across your entire catalog.

Fixed Costs vs. Variable Costs (and How to Reduce Them)

There are two distinct types of costs associated with your products. Understanding the difference is crucial when strategizing how to reduce costs.

Fixed Costs

Fixed costs are precisely what they sound like: fixed. These expenses do not (or rarely) change and usually apply to multiple products. Some of the most common examples of fixed costs include:

- Labor.

- Warehousing.

- Utilities.

- Equipment and asset maintenance.

- Security.

- Platform and channel subscriptions.

Any time you can reduce these operational costs, you stand to reduce the per-unit costs of multiple SKUs simultaneously. There are several effective ways to do so:

- Optimize your hiring and retention practices to reduce unnecessary labor expenses.

- Revamp your warehousing infrastructure with multiple warehouses and a decentralized fulfillment strategy.

- Find and establish warehouse locations ideally suited to your ecommerce business.

- Opt for a unified, affordable ecommerce platform rather than combining multiple, more expensive options.

Descartes Sellercloud’s family of products is ideal for identifying and implementing these business-wide changes. Our omnichannel ecommerce growth platform, combined with Skustack, our patented warehouse management system (WMS), gives you all the reporting tools you need to identify operational issues and address them in ways that will save you money.

Variable Costs

Variable costs are those subject to changes and fluctuations in ways that fixed costs are not. Moreover, they often affect the individual products in your catalog differently. They include things like:

- Manufacturing.

- Packaging.

- Supply chain costs.

- Shipping.

- Marketing.

- Customer service.

While there are some instances where optimizing variable costs for a particular product reaps benefits for other products (like negotiating a more favorable shipping partnership), reducing variable costs is critical when bringing down the per-unit costs of individual SKUs.

Even if a cost-per-unit optimization only affects a single SKU, it is usually worthwhile. Variable cost elements have the potential to generate some of the most substantial savings. To bring down these variable costs:

- Seek out more affordable and reliable vendors and suppliers.

- Improve product quality to address customer concerns and reduce return and refund requests.

- Assess and optimize product packaging.

- Negotiate with multiple shipping partners to keep fulfillment costs down.

- Take advantage of pay-per-sale marketing tools like eBay’s Promoted Listings and Google Shopping to eliminate paying for advertising that doesn’t convert.

Descartes Sellercloud’s 350+ integrations mean that you can create and manage the relationships that will propel your omnichannel ecommerce business to new heights of profitability on both the brand-wide and product-by-product levels.

Where to Look for the Best Odds of Cost Per Unit Savings

Ideally, all the products you list and sell should be optimized for the highest possible profit per unit. While this calculation also involves factors like pricing strategy and product returns, it all starts with the cost per unit. When deciding where to start your unit cost optimization efforts, a few approaches can increase your chances of generating immediate results.

Prioritize the SKUs with the Lowest Profit Margins

When you examine your profitability reports, make it a point to give immediate attention to any SKUs that are generating slim or negative profit margins. Doing so can revive an underperforming product and surface larger issues that may negatively impact other products. In some cases, diminishing or nonexistent profit margins may indicate that a product is reaching the end of its life cycle.

But before you decide to phase a product out entirely, be sure that you have exhausted fixed cost and variable cost optimizations that could rejuvenate an SKU instead of leaving you with a load of dead stock to contend with.

Optimize Your SKUs with the Highest Order Volume

You may be reluctant to do anything that could disrupt the success of your top-performing products. However, an attitude of “if it ain’t broke, don’t fix it,” could prevent you from a prime opportunity to improve your bottom line. Even a minor optimization that leads to cost savings for your best sellers could boost profits when multiplied across a high order volume.

You may be able to leverage strong order numbers to negotiate supplier quantity discounts. Investments in packing optimization could significantly dent your shipping and handling costs. Even moving popular items closer to the order processing area of your warehouse could improve fulfillment efficiency enough to make a difference.

Descartes Sellercloud’s ecommerce growth platform gives you the tools to track unit costs and implement meaningful inventory management and workflow changes that can lead to increased profitability.

Contact us directly for a free demo, and see how our platform and tools can empower your team to get the most out of your online sales business.