Key Points

- Peak season puts maximum pressure on warehouses, requiring efficiency and capacity optimization.

- Warehouse optimization strategies can reduce bottlenecks and improve throughput.

- Capacity planning and scalable systems are critical for peak-season resilience.

- Descartes Sellercloud’s warehouse management system (WMS) module (Skustack) and Descartes Peoplevox support optimized warehouse operations during peak and beyond.

Peak season is the ultimate stress test for any peak season warehouse. From surging order volumes to staffing challenges and limited space, it exposes every inefficiency in your operation. Bottlenecks in picking, packing, or shipping quickly escalate into missed deadlines and unhappy customers.

In this guide, we explore how warehouse optimization solutions can help you survive peak season 2025. We’ll also cover practical tips and best practices for capacity planning, workforce management, logistics, and technology adoption—all designed to keep your warehouse efficient under pressure.

Understanding Peak Season Pressure on Warehouses

For warehouses, peak season isn’t limited to the holidays. It could be a summer sale, back-to-school rush, or any period of elevated demand. Regardless of timing, the challenges are similar.

Space quickly runs short, picking slows down as aisles get congested, packing stations back up, and errors slip through as staff work under pressure. Without optimization, these inefficiencies ripple across the fulfillment chain, driving up costs and leading to late deliveries.

Warehouse Optimization Strategies for Peak Season

Clear warehouse optimization strategies can make the difference between chaos and control. Redesigning layouts so that goods flow smoothly from receiving to shipping reduces wasted steps. Strategic slotting—placing high-demand SKUs near picking areas—cuts time per order.

Cross-docking speeds up fulfillment by minimizing handling, while zoning helps balance workloads and prevent bottlenecks. You can dive deeper into warehouse layout best practices in this blog post.

Planning for Warehouse Capacity Optimization

When it comes to warehouse capacity optimization, visibility and foresight are key. Start by measuring current storage and throughput to understand limits. If demand will exceed capacity, consider temporary storage or off-site facilities.

Using vertical space with racking or shelving upgrades helps stretch square footage further. Coordinating inbound shipments in staggered waves prevents docks from being overwhelmed. With careful planning, you can keep throughput steady even during peak surges.

Staffing and Workforce Management During Peak

People are as critical as processes. Hiring seasonal staff early allows time for proper training before the rush hits. Many warehouses rehire proven seasonal workers from prior years to reduce onboarding time. Rapid training materials and standard operating procedures (SOPs) help new staff get up to speed quickly.

Cross-training employees adds flexibility, ensuring shifts don’t stall if one role is short-staffed. Ergonomics and safety should remain a priority, protecting both productivity and worker well-being. For more, see this article on warehouse roles.

Warehouse Logistics Optimization

Efficient logistics flow is another cornerstone of success. Warehouse logistics optimization means synchronizing inbound and outbound schedules so that trucks don’t compete for limited space.

Ensure clear staging areas for carriers, keep outbound lanes organized, and reduce congestion. Eliminating unnecessary handling steps accelerates order flow. Technology like digital picklists and mobile scanning devices streamlines task assignment and minimizes errors.

Data Visibility and Performance Metrics

Optimization starts with knowing how your warehouse is performing. Tracking metrics like picks per hour, throughput time, dock-to-stock cycle time, and error rates gives you a clear picture of where bottlenecks occur. With this visibility, you can forecast staffing needs, adjust workflows, and ensure that orders move through your warehouse without delays.

Real-time reporting and dashboards also let managers respond quickly during peak. Instead of waiting until the end of a shift to find issues, you can act immediately to prevent backlogs.

Key warehouse metrics to track during peak season:

- Picks per hour—Measures staff productivity.

- Throughput time—Tracks how long orders take from picking to shipping.

- Dock-to-stock cycle time—Shows how fast incoming goods are ready for picking.

- Order accuracy rate—Identifies errors that cause costly returns or delays.

- Inventory turnover—Highlights how quickly stock moves through your warehouse.

Technology-Driven Warehouse Optimization Solutions

Technology powers today’s most resilient warehouses. Mobile scanning and real-time tracking provide immediate visibility. Reporting and analytics highlight bottlenecks before they escalate.

Automation reduces repetitive tasks, from generating picklists to replenishing stock. With the right warehouse optimization solutions, operations scale dynamically without requiring a proportional increase in staff.

Peak Season Survival Checklist for Warehouses

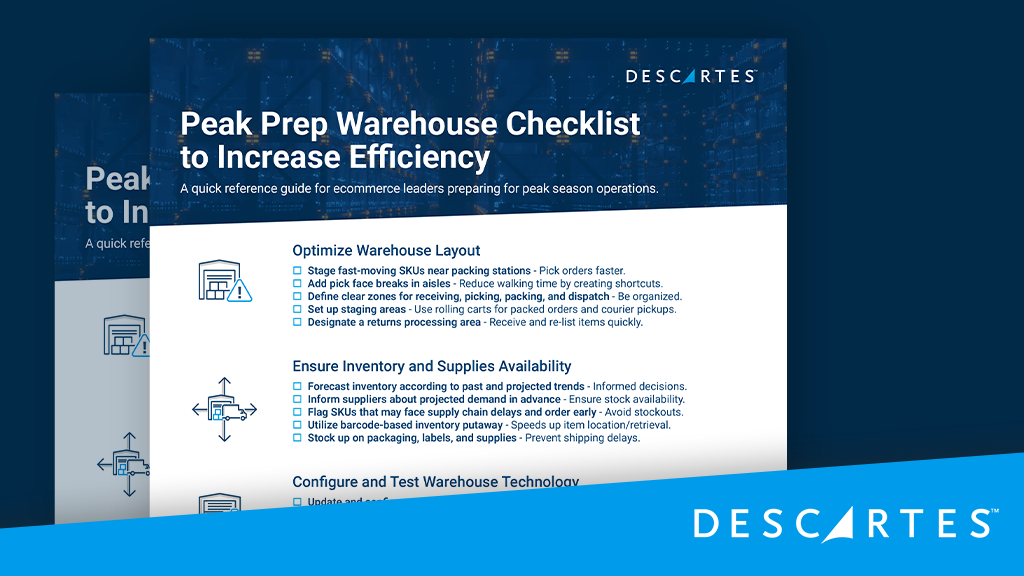

Preparation is everything. Review your floor layout and adjust slotting before demand spikes. Test equipment, such as scanners, printers, and forklifts, to avoid breakdowns in the middle of a rush.

Update safety procedures and hold daily shift meetings to keep teams aligned. Finally, stress-test your WMS to confirm it can handle peak transaction loads without performance dips.

For additional preparation, check out our Peak Prep Warehouse Checklist, a practical resource designed to increase efficiency and resilience during peak season.

After Peak Season–Futureproofing Your Warehouse

Once the rush is over, take time to evaluate. Review performance data and identify where delays or errors occurred. Consider structural upgrades like conveyors, automation, or racking that can expand throughput.

Many optimizations tested during peak—such as slotting changes or better workflows—are worth keeping year-round to strengthen resilience. Regular audits ensure your warehouse optimization strategies evolve alongside your business.

If growth requires more space, see Descartes Sellercloud’s guide to moving warehouses.

Why Descartes Sellercloud Is Built for Peak Season Warehouses

Descartes Sellercloud’s Skustack WMS module equips warehouses to thrive under pressure. It enables mobile-first operations, bin-level tracking, and barcode scanning while providing real-time visibility into inventory and order progress.

These tools are proven to improve efficiency and reduce errors. What sets Descartes Sellercloud apart is its combination of an order management system (OMS) and WMS, creating seamless readiness for peak and beyond.

For high-growth direct-to-consumer (D2C) brands, you can use Descartes Peoplevox, a WMS designed for high-volume growth. Together, these solutions adapt to your needs and ensure your warehouse stays optimized year-round.

Book a Descartes Sellercloud demo today to discover how we can help you manage your warehouse during peak season with confidence.